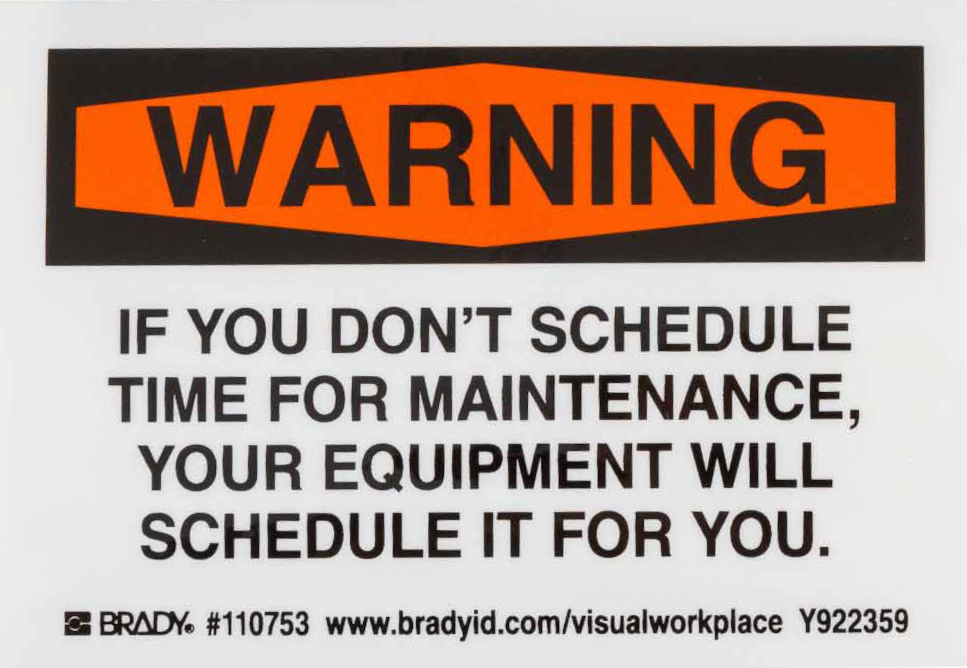

Scheduling Time For Maintenance

This is a real thing you can buy.

Brady is all about labeling for the workplace. They’re primarily aimed at the manufacturing/processing space. They’ve got a product line directed at lean manufacturing techniques, such as those that come out of the Toyota Production System (TPS), which I’ve talked about before. Since a lot of today’s agile and lean software development processes are derived from TPS and lean manufacturing some of them make a lot of sense in the software world as well.

We don’t have machines or storage racks that you could put that sticker on, but putting it somewhere prominent, like on your laptop or next to your monitor, so you don’t forget about it might make sense.

But what does it really mean for software? After all, no matter how many times you run an executable or iterate over a loop the ones don’t wear down to .6 or .7 and the zeros don’t start to fill in and turn into .3 or .4? The code, barring disk errors and cosmic rays, doesn’t change.

There are a few things that maintenance implies with software. Unless you’re running on an embedded system and there is no operating system you’re relying on third party code. And even if your code is perfect there are going to be changes and updates to someone else’s code you want to use. It could be to pick up new features or better performance, or it could be to close a security loophole, like the log4j issue. So there’s always a reason for maintenance.

Even without those reasons for maintenance, you probably want to do something to the code. Add a feature. Respond to new business requirements. Reduce support burden. All of those things are maintenance. And sometimes, to enable that kind of maintenance, you need to do internal work. To keep the external software quality (ESQ) high, you need to work on the internal software quality (see ISQ vs ESQ).

That’s where scheduled maintenance comes in. Doing the extra work so you can do the required work. The unseen work that lets you keep your velocity up. The unseen work that lets you respond to changes in the environment quickly. The unseen work that lets you add value.

Which means there is value in that unseen work. So don’t skimp on it.